Prototyping

- Capabilities

- Prototyping

Guaranteed Highest Quality

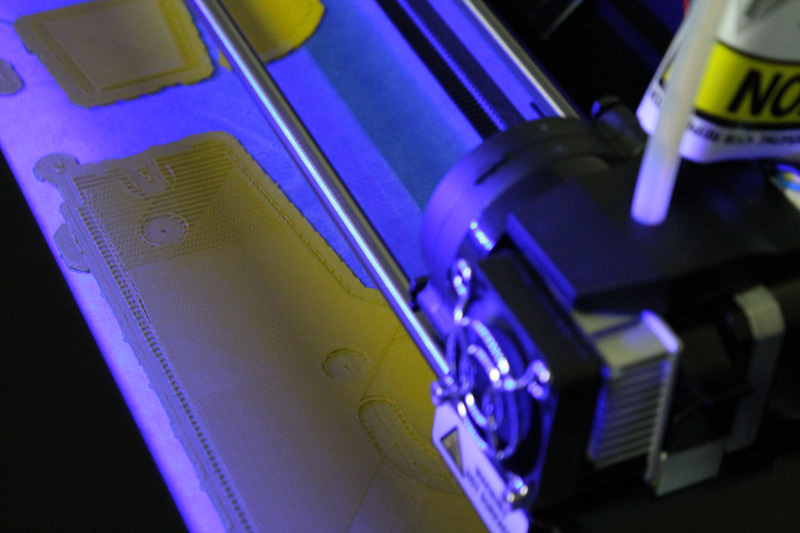

Automation Tool & Die manufactures high-quality, functional prototypes of proposed part designs so they can be tested for proper form, fit and function before final production runs begin. Our prototypes are made with the same attention to detail and processed through the same Quality Management System as our finished stampings.

%20(1).jpg)

Backed By Expertise & Innovation

Customers look to our engineering expertise to design a part that’s going to work. We support them with up-front information including 3D modeling, simulations and prototype builds. While we may fabricate them differently, it's always in a way that truly represents the final production part.

Explore Our Other Capabilities

Limit transportation and handling costs and avoid outsourcing components to secondary vendors. As a one-stop shop, ATD offers a range of capabilities to meet the unique needs of your business, from beginning to end.

.jpg)

ATD's CAD Expertise Produces Big Cost Savings for Automotive Manufacturer

Learn how ATD saved an automotive manufacturer hundreds of thousands of dollars by using CAD software to pinpoint a failure and design a new part.

“We were able to tell them that if they went down the path they’ve used for these other tools they’ve built and are running, this part is going to fail. Right up front, in the very early stages of the laying out of this tool, we were able to get that in front of them — before steel was ordered, before die was set, before a lot of costs were accrued.”

Robert Matis

ATD Senior Tooling Engineer and Estimator

What Our Customers Say

Find out what others have to say about ATD's one-stop shop model for custom, high-quality products and services that are backed by expertise and state-of-the-art technology.

“I appreciate ATD’s teamwork environment, philosophy and vision. I am happy to see the family-like environment at ATD and the ATD team's willingness for long-term partnership, which is in line with our owner’s vision."

Sales Manager

Automotive Manufacturing Company

"ATD is a world-class organization with a high level of expertise — and we have never regretted partnering with them for nearly all of our stamping and tooling needs since we started working with them in the late '90s. The communication is excellent, and they are transparent in all they do — pricing, quality, working together through any sourcing challenges that may come up from time to time, helping to accommodate us when demand unexpectedly spikes on certain parts — the list goes on. They are a true partner and we consider them an extension of our business."

President

Industrial Manufacturing Company

“ATD has the staff, knowledge, and ability to meet your needs."

Associate Engineering Supervisor

Automotive Manufacturing Company

Discover What We're Capable Of

Partnering with ATD means receiving the quality products, services, timeliness and problem-solving support you need to win more customers.